HPL Cleanroom Wall: Efficient and Hygienic Solution for Clean Environments

The design and construction of cleanrooms require meticulous attention to detail to maintain the highest standards of cleanliness and contamination control. One essential component in creating a clean and controlled environment is the HPL (High-Pressure Laminate) cleanroom wall system. With its exceptional properties and versatility, HPL is becoming increasingly popular in cleanroom applications.

HPL false ceilings and walls offer a range of benefits that make them ideal for cleanroom environments. The HPL ceiling acts as an overhead barrier, effectively sealing the area and preventing contaminants from entering the controlled environment. Its durable and non-porous surface is resistant to dirt, bacteria, and chemical agents, ensuring easy cleaning and maintenance.

The cleanroom HPL partition walls provide a modular and flexible solution for space division within the cleanroom facility. These partition walls are designed to seamlessly integrate with the cleanroom infrastructure, creating separate zones while maintaining the required cleanliness levels. The HPL partition walls offer excellent sound insulation properties, helping to minimize noise transmission between different areas of the cleanroom.

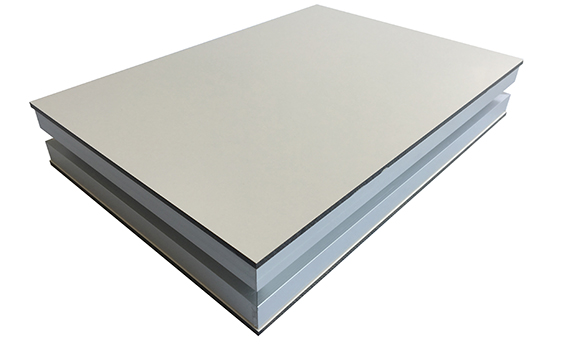

The cleanroom HPL walls themselves are constructed using high-pressure laminates that are engineered to meet the stringent hygiene standards of clean environments. These panels are smooth, homogeneous, and non-shedding, preventing the release of particles into the air. The HPL material is also resistant to scratches, impact, and chemical agents, ensuring long-lasting durability.

The HPL partition wall system offers versatility in design and customization. It can be tailored to meet specific cleanroom requirements, providing options for different finishes, colors, and accessories. This flexibility allows for easy integration of utilities, such as electrical wiring, ventilation ducts, and plumbing, within the cleanroom walls.

Furthermore, the HPL partition system is designed for easy installation and reconfiguration. With its modular nature, the cleanroom layout can be adjusted and modified as needed, providing adaptability to changing operational needs. The quick installation process minimizes downtime during construction or renovation projects.

To ensure the highest quality and performance, it is crucial to source HPL cleanroom wall systems from reputable manufacturers with expertise in cleanroom solutions. These modular clean room manufacturers understand the unique requirements of clean environments and provide certified products that comply with industry standards.

In conclusion, the utilization of HPL cleanroom wall systems, including HPL false ceilings and partition walls, is a smart choice for creating efficient and hygienic cleanroom environments. With their excellent properties of durability, cleanliness, and customization, HPL walls contribute to maintaining the integrity and performance of cleanroom facilities. By working with trusted cleanroom solution providers, such as modular laboratory buildings manufacturers, organizations can ensure the successful implementation of cleanroom projects that meet the stringent requirements of their industries.